Integral

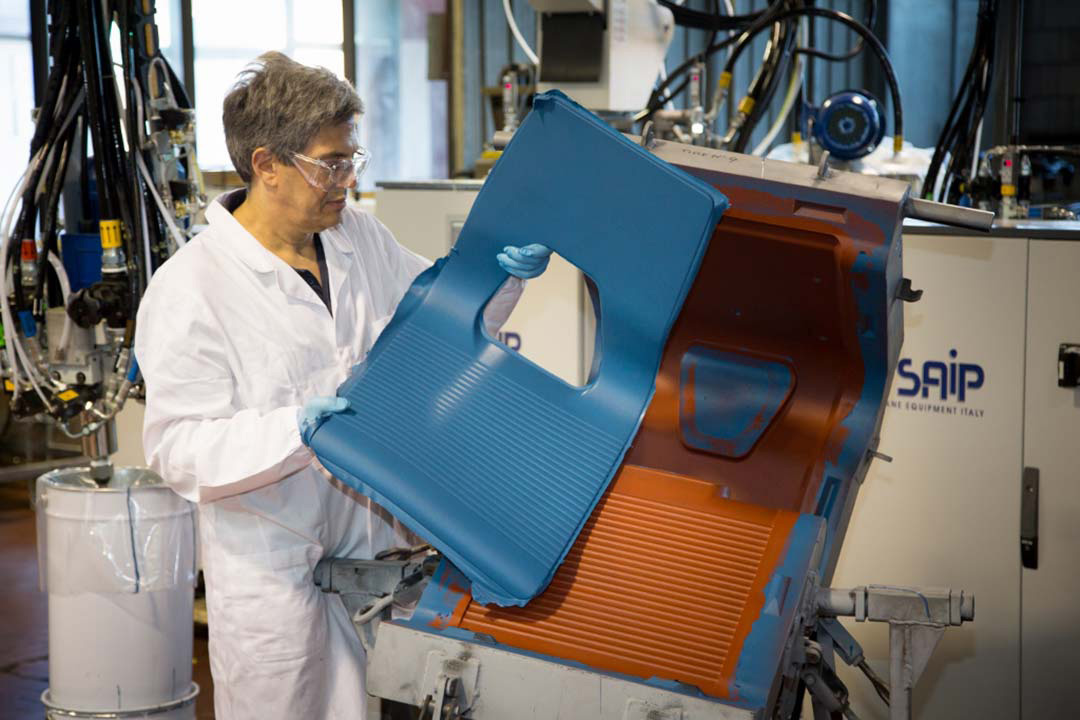

This polyurethane foam is used to produce artefacts with a very compact and detailed outer surface. The finished product is aesthetically pleasing, resistant to wear and tear, it faithfully reproduces the surface design of the mould and provides the feel of real leather.

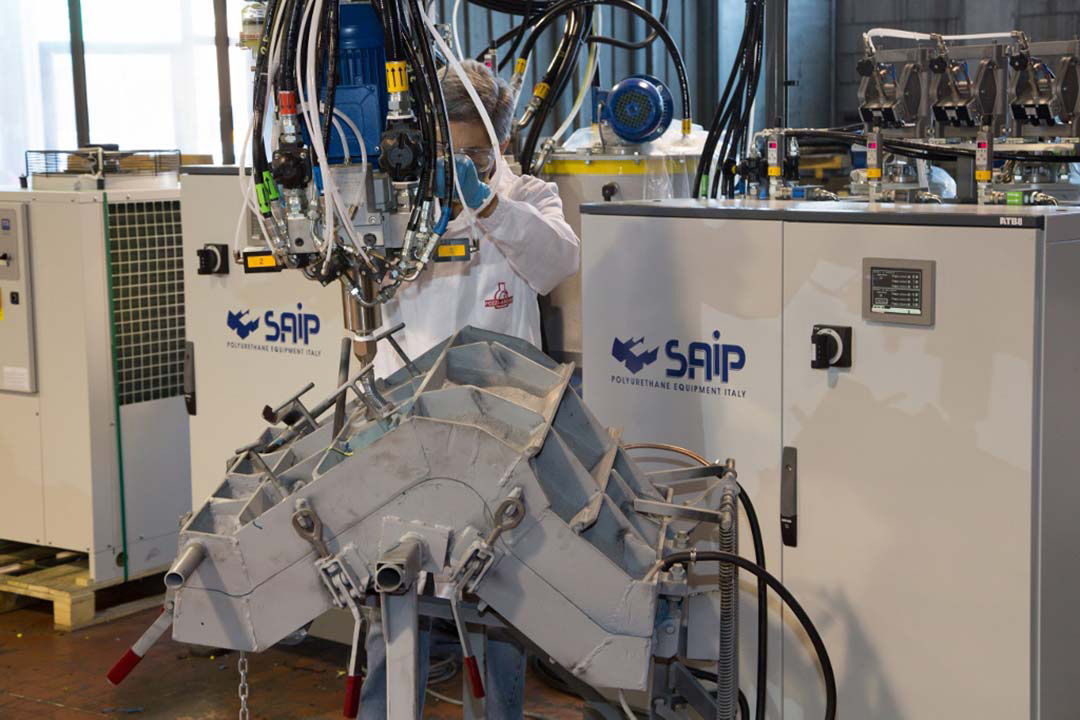

This type of product is obtained with thermostatically controlled moulds made of resin or metal that normally operate at a temperature between 40 and 50 °C.

The mould is generally black or neutral in colour, but with the in-mould coating technique, colours from the RAL or NCS table can also be applied. This system allows the positioning of inserts directly in the mould before casting (various inserts and metal frames).

Both high-pressure and low-pressure foaming machines are used for production.

Properties

- Density 250 to 450 kg/m³

- The insert is incorporated inside the foam

- The foam remains homogeneous throughout

- Used for elegant and designer shapes

- Production creates complex shapes in a single step

- You can create subtle but also very important thicknesses